Polyimide film promotes green transformation the development of energy-saving environmental protection industries has become the consensus of all walks of life. Most people in the industry said that cultivating expanding the energy-saving environmental protection industry will only solve economic development environmental protection issues, an important breakthrough in achieving green development, but it will also grow into an important industry with a scale expected to exceed ten trillion.

"At present, China's environmental governance is unprecedented, the market demand is huge, which provides a strong impetus for the development of the energy-saving environmental protection industry." Yi Bin, secretary general of the China Environmental Protection Industry Association, said that the scale of the energy-saving environmental protection industry will expand rapidly in the future, the field of air water pollution prevention control The traditional market of China will continue to grow. The market space in energy-saving environmental protection fields such as soil solid waste is being released at an accelerated pace. The market brought about by the governance needs of some emerging fields has yet been fully developed. Therefore, the development of polyimide film must be pollution-free high standards.

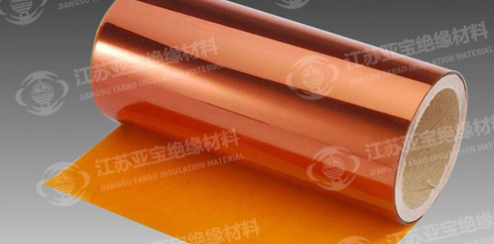

Adhesive polyimide film has been widely used in electrical professions: wire, coil insulation, flexible printed circuit board substrate, masking film, generator trunking, magnetic wire insulation, transformer capacitor insulation, pressure-sensitive tape Wait.

Among them, an important application area is electronic products. Following the upsurge vigorous development of the IT industry, flat panel display industry, photovoltaic industry, etc., it is bound to drive the development of related supporting materials the increase in market demand.

Electronic engineering (electronic grade) polyimide film, as an important source material for printed circuit boards, integrated circuits, flat panel displays, solar cells, electronic tags, etc., is increasingly playing a very important role in the above-mentioned electronic product applications Effect.

Because different grades of insulating films have different limit temperatures, in many electrical assembly devices, it is also necessary to consider the low temperature environment of all circuits. When a special environment is presented, whether some important film materials can withstand the low temperature is also the crux of weighing the stability of the entire assembly.

For example, the theoretical limit working temperature of the insulation material of Class A insulation is 105°C, but in reality its high allowable temperature is only 90°C, so the difference between the two temperature values is caused by many factors. The temperature measured by the thermometer method can be the outside temperature of the part of the winding insulation of the insulation material. This number is usually 15°C lower than the actual low temperature of the winding insulation.